How Hydraulic Fracturing Works

© Copyright 2010 Pro Publica Inc. (https://www.propublica.org/article/hydraulic-fracturing-national)

Why Drill the Marcellus Shale?

Fossil fuel prices have increased substantially within the past decade, making unconventional methods of fuel production far more economically viable on a large scale. These methods are far more expensive than conventional drilling, but are becoming increasingly necessary as supplies dwindle and demand soars. Hydraulic Fracturing is a method of unconventional natural gas development that produces gas from shale formations. Such shale formations are located throughout the United States: there are formations in Texas, New York, Pennsylvania, West Virginia, and many other states throughout the country.1

Shale formations are a type of sedimentary rock, which is a type of rock that is formed as organic and mineral matter settles within water basins. Fossil fuels, including oil and natural gas, are formed by decaying organic material in the subsurface. Depending on the composition of the sediment that forms the rock, shale formations can be very good sources of fossil fuels. The Marcellus Shale formation is one of many gas shale formations throughout the United States that has an abundant supply of natural gas trapped within it. In the state of Pennsylvania, it covers 33,114 square miles, representing 73 per cent of the total land area.2

Drilling the Marcellus Shale

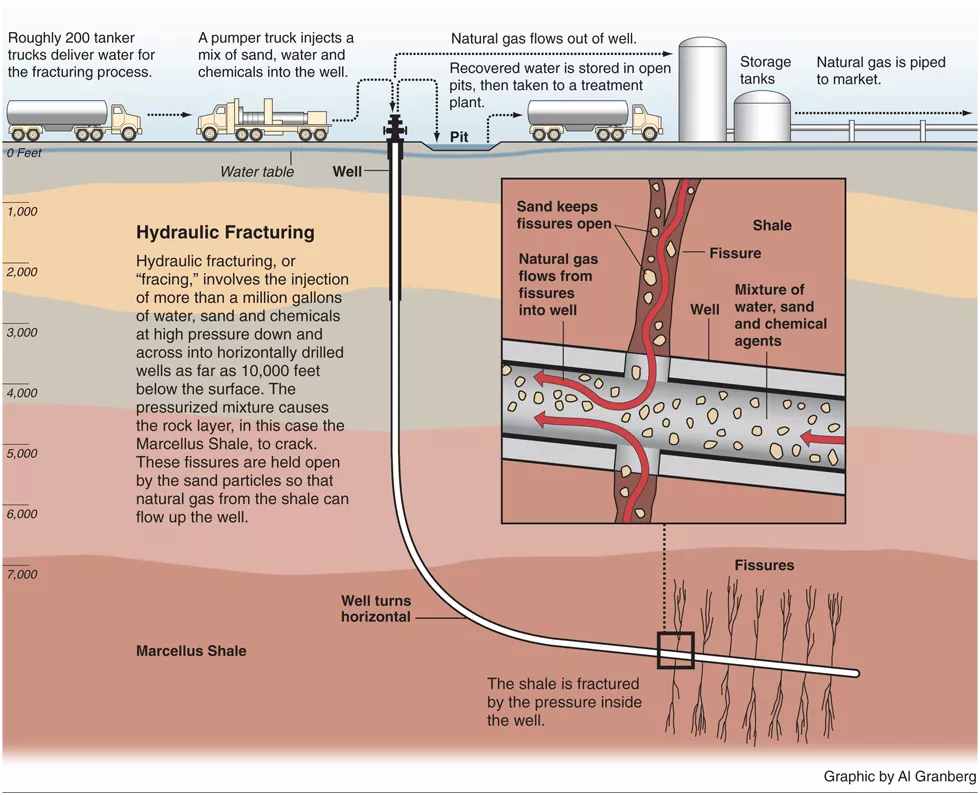

Hydraulic Fracturing wells can be drilled either vertically or horizontally. Horizontal wells are more expensive and difficult to drill accurately than vertical wells, but they allow the operator to extract more gas from a single well, vastly reducing the impact on the surface and increasing the economic viability of the well. The Marcellus shale lies below the drinking water aquifer, and is separated from the aquifer by rock of extremely low permeability. After the well is drilled, it is cased in steel and concrete to prevent the well from caving in on itself and to prevent fracturing fluid and natural gas from migrating into the groundwater supply.

Fracturing

Although the amount of gas available in the Marcellus shale is tremendous, shale formations generally have extremely low permeability, ranging from 0.01 to 0.00001 millidarcies. Typical oil reservoir formations have permeabilities ranging from 100 to 10,000 millidarcies. This low natural permeability means that any gas production wells drilled into the formation will not be able to produce enough natural gas to make the well economically viable. Hydraulic fracturing is a process that is used to increase the permeability of the shale formation so that gas is able to migrate towards the well.

The hydraulic fracturing process begins by injecting water to fracture the subsurface shale formation, increasing permeability and hydraulic conductivity. Sieved sand is added as a "proppant" to keep the newly fractured rock from closing back up. The sand also provides a medium for the fracturing fluid to pass through. In addition to water and sand, small concentrations of chemical additives are used to further increase productivity. These additives typically include chemicals to reduce friction within the well and allow the proppant to travel through the rock fractures effectively, to prevent the growth of algae and bacteria that would harm the well system, and to prevent well pipe corrosion. Common additives are listed in Table 1, and typically make up between 0.05 to 0.5 % of the total fluid volume.3,5

Although some of these chemicals are harmful, it is very important to note that they are being injected at extremely low concentrations; most of the fracturing fluid is clean, sieved sand and water. Engineers and geologists determine the exact composition of the fracturing fluid, including volume and injection pressure. This is typically done using a computer simulation program that is able to run a three dimensional analysis of the subsurface conditions. These programs have the capability to specify the operation of the well pumps, anticipate the fracture dynamics, and specify the optimal proppant and chemical mixture within the fracturing fluid.4

References

1. Arthur, J. Daniel et. al. "Hydraulic Fracturing Considerations for Natural Gas Wells of the Marcellus Shale."

2. Eichenwald, Zachary. GIS Calculations. April, 2010.

3. Marcellus Shale Coalition. "Hydraulic Fracturing." Updated 2009. http://www.pamarcellus.com/fracing.php.

4. Meyer & Associates, Inc. "MFrac" www.mfrac.com/mfrac.html

5. NY Department of Environmental Conservation. "Marcellus Shale." Updated 2010. http://www.dec.ny.gov/energy/46288.html